Palfinger goes XR: Virtual crane experience as an app

Palfinger goes XR: Virtual crane experience as an app

Palfinger goes XR: Virtual crane experience as an app

Palfinger goes XR: Virtual crane experience as an app

Mechanical Engineering

Mechanical Engineering

Mechanical Engineering

Mechanical Engineering

With

Johannes Rehrl

Manager Global Sales Tools

Manager Global Sales Tools

INDUSTRY

Mechanical Engineering

Benefits

Interactive 3D Animations

Mobile App

Augmented Reality

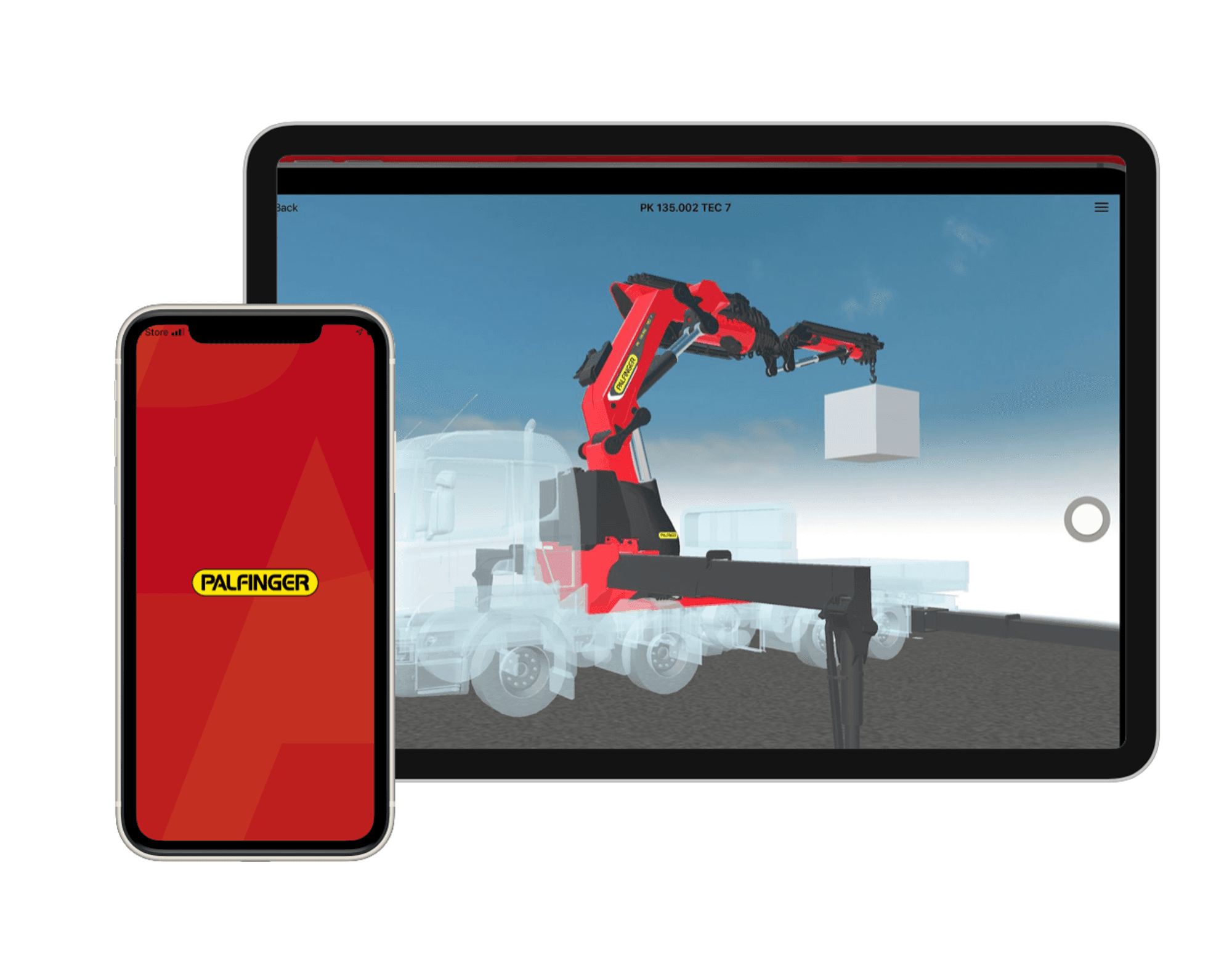

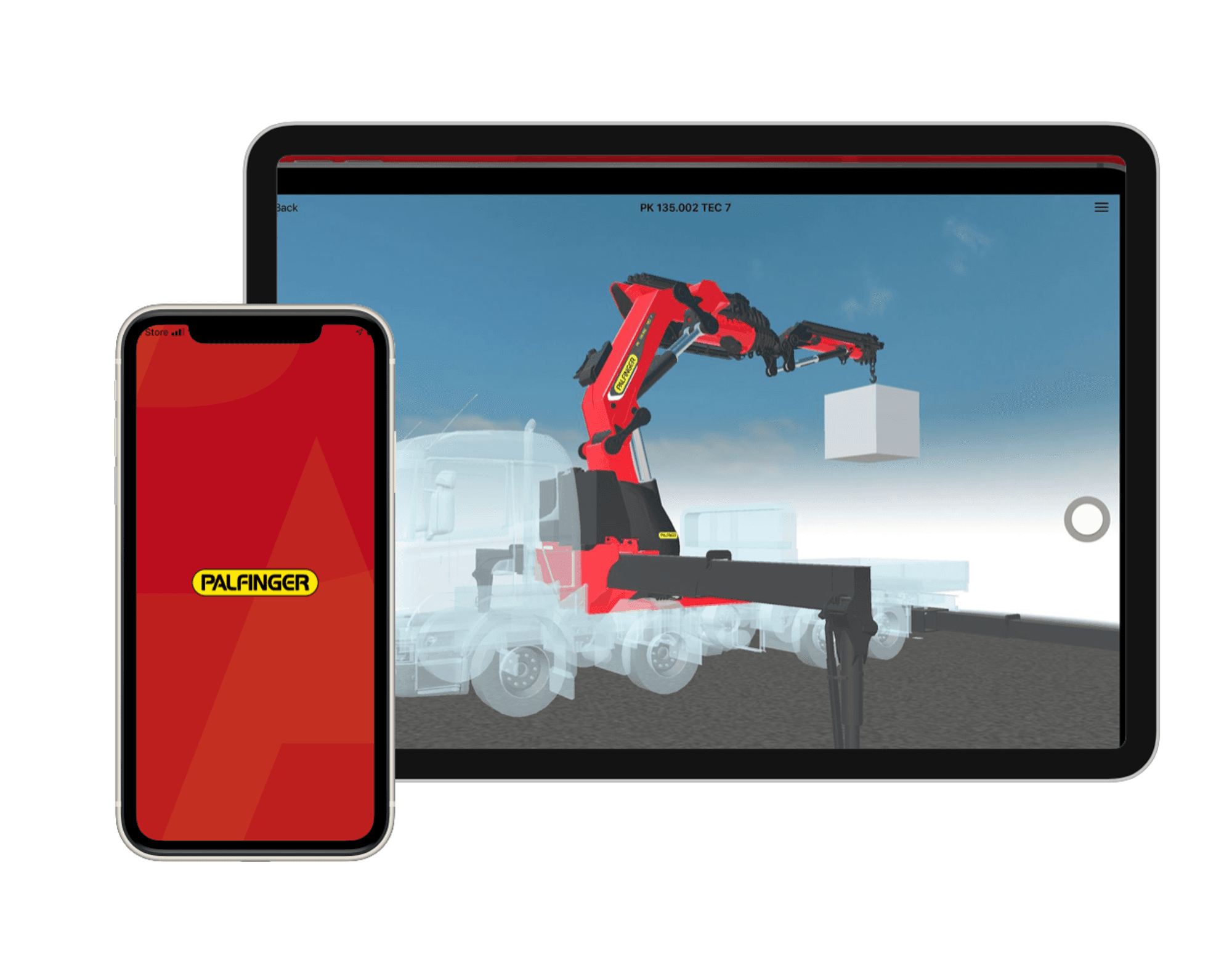

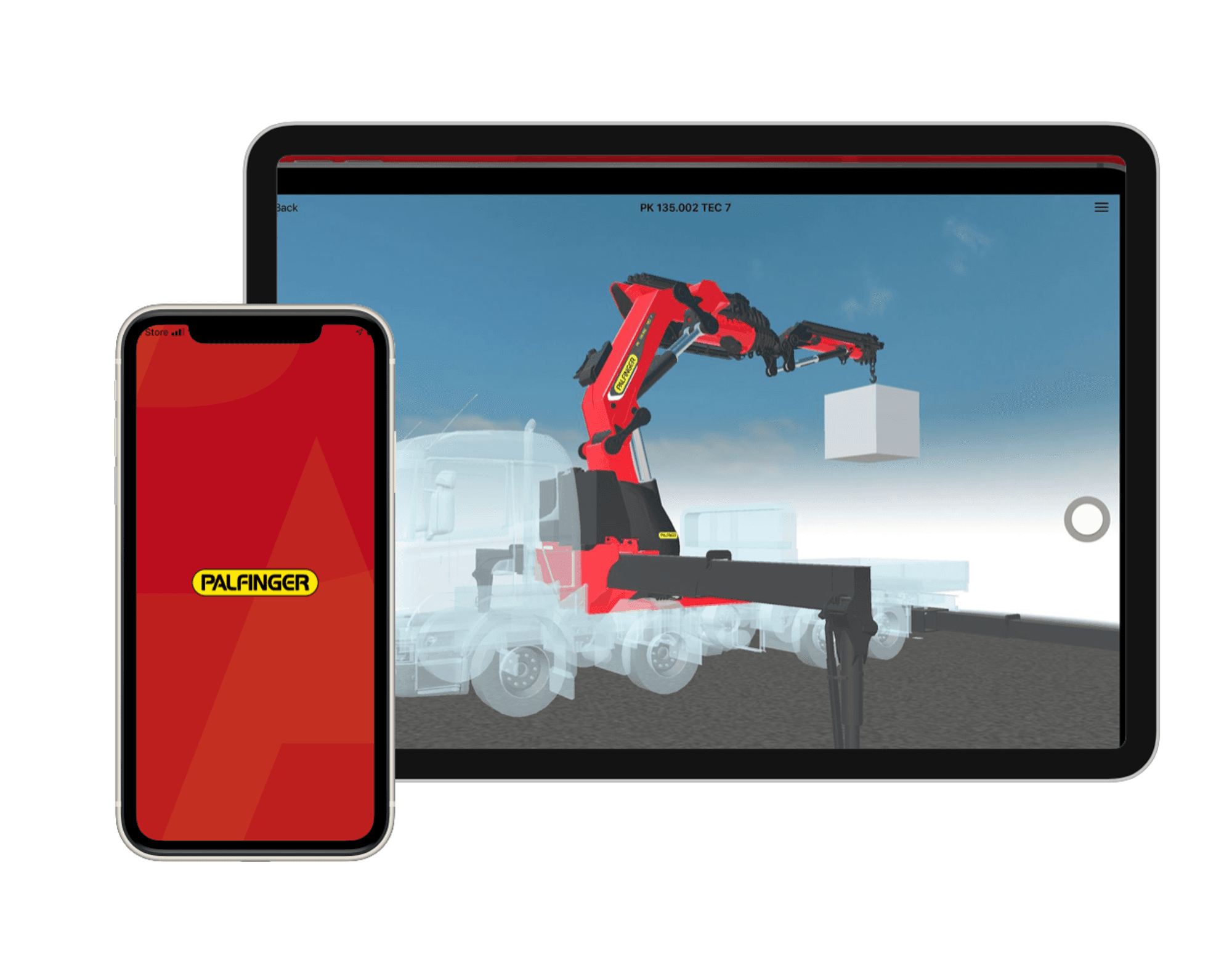

PALFINGER AG has created and launched a brand new “Palfinger XR” app with Vuframe® that will bring products and manuals closer to thousands of customers in the future.

The customer: PALFINGER AG

Founded in 1932, the company is known worldwide for the most innovative, reliable and economical lifting solutions used on commercial vehicles, ships and stationary equipment. Innovation and further internationalization of products, processes and services are the three pillars of the company's strategy, along with flexibility.

Solutions, which are used on commercial vehicles, ships and stationary equipment. Innovation and further internationalization of products, processes and services form the three pillars of the corporate strategy, alongside flexibilization. In order to focus on the challenges and opportunities of the digital transformation, a fourth pillar has been added to the tried-and-tested strategy: PALFINGER 21st stands for new core competencies, new approaches, new products, services and business models in the digital age.

PALFINGER in figures at a glance

1,534 millioneuros in revenue in 2020

10,824 employees worldwide

34 production and assembly sites

5,000 manufacturing and assembly sites

Demo video of the PALFINGER XR app

The challenge: Own administration and compact, secure data

From the agency to the SaaS platform

Originally, an XR app was developed with an agency. However, it soon became clear that PALFINGER was constantly developing its products and in order to reflect these changes in the app, the company always had to turn to the agency - with the associated costs, of course.

In addition, two important requirements could not yet be met:

Complex, animated 3D models of the lifting machines could not yet be compressed as small as desired without causing a loss of visual quality.

The question of data security for the 3D models played out, which were created from design data, could also not yet be adequately answered.

PALFINGER therefore turned to Vuframe because the platform allows users to manage the app themselves and is unique on the market in terms of data compression and data security thanks to its proprietary Aura 3D technology.

The solution: The PALFINGER XR app from Vuframe®

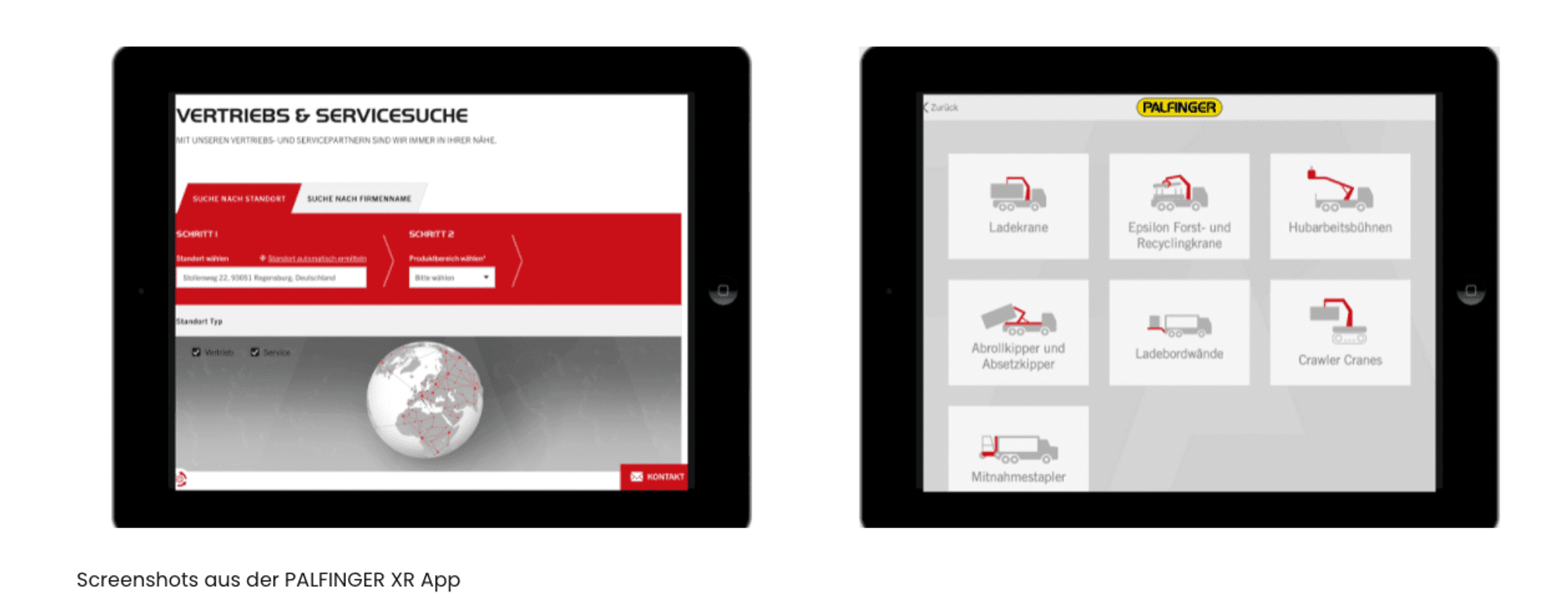

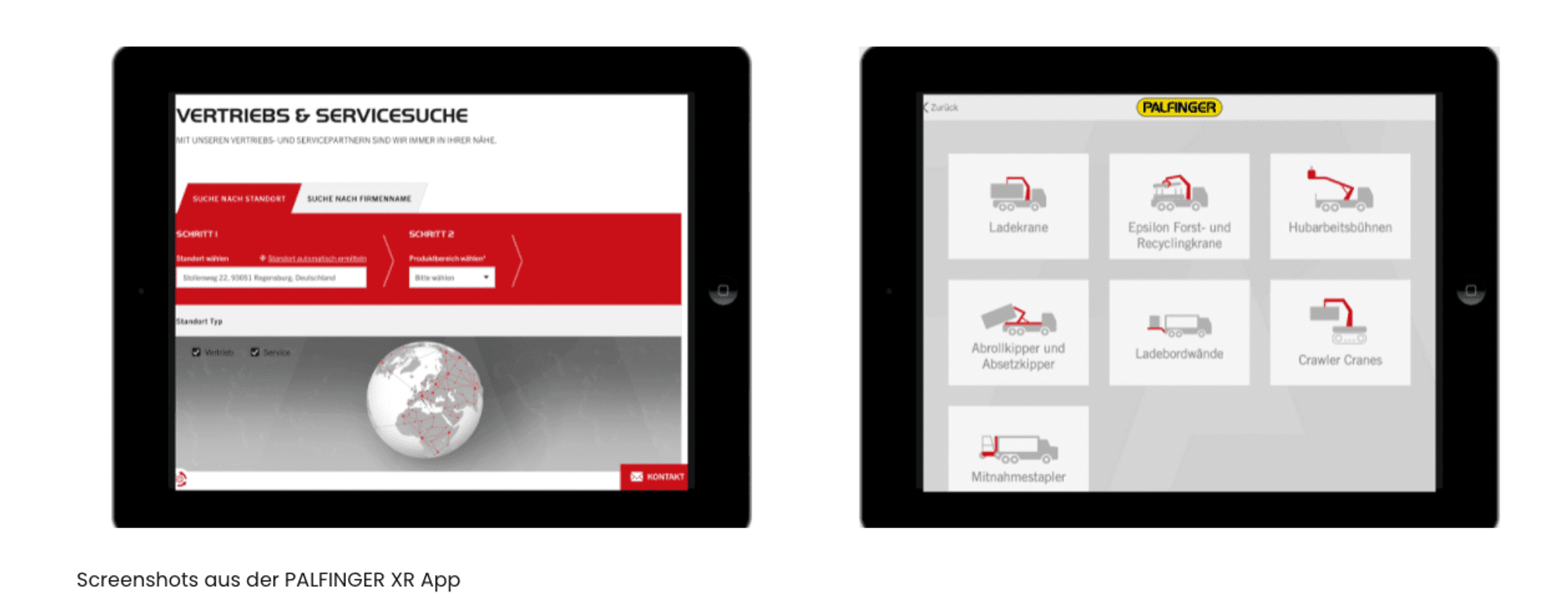

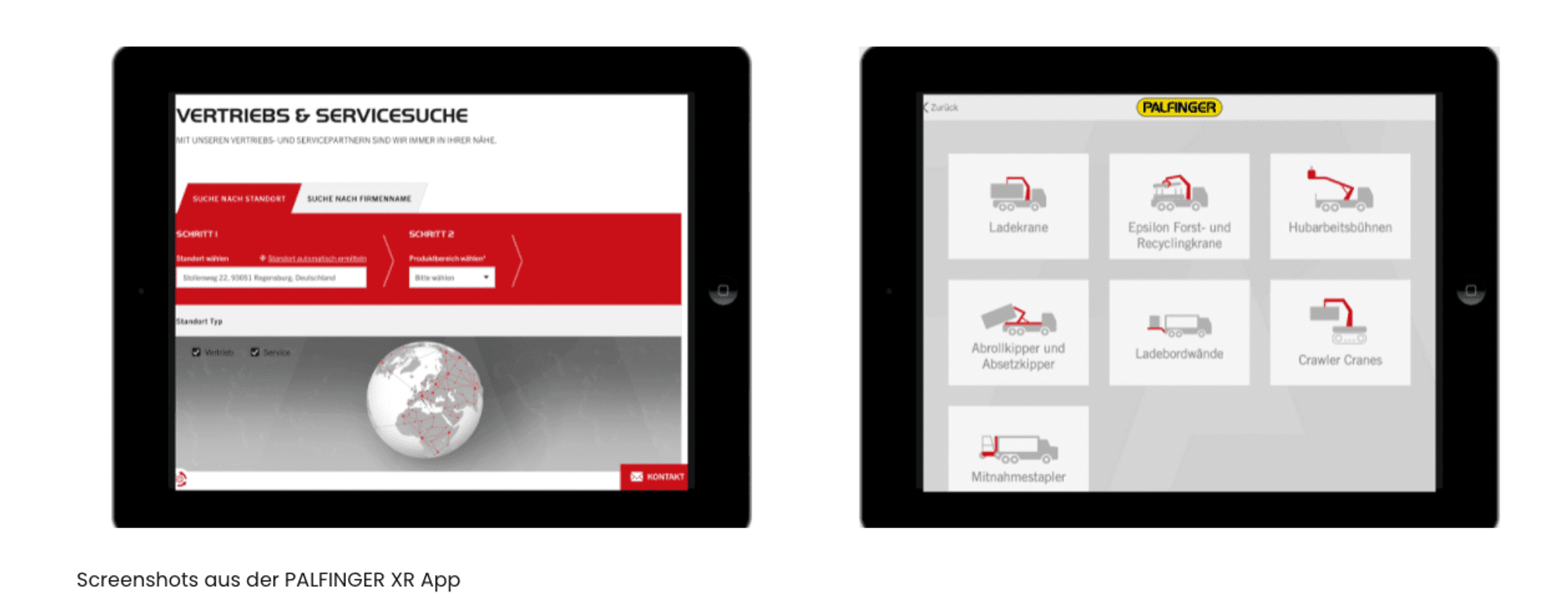

Use in various areas

The XR app solution kills two birds with one stone and serves two use cases at once - it is a sales solution and digital customer service at the same time:

In the app, the product portfolio can be presented by sales staff in 3D and augmented reality. The digital twins easily solve logistical challenges, especially for large crane constructions.

The app's AR marker recognizes videos stored in operating instructions that serve to illustrate PALFINGER machines and visually explain processes, for example. A classic, physical manual is therefore digitally supported for the customer. Palfinger then manages the content of the AR marker and the app structure itself in Vuframe Studio.

How the AR marker of the PALFINGER XR app works

Special feature: the AR marker

Seamlessly combining reality and digital

By selecting the AR marker in the PALFINGER XR app, customers can read additional digital information from the operating instructions using their smartphone or tablet camera. In most cases, these are stored videos that visually explain a specific procedure for operating or maintaining the crane in question.

The advantage: the videos are already stored in the right place in the operating instructions and there is no need to search by model and application, for example on the PALFINGER website, to find out specific handling or procedures. All that is needed is a mobile device so that customers can get the information they need even when they are standing directly in front of the machine in question.

“We have converted the existing PALFINGER XR app to the Vuframe platform. Now we can maintain & update the app ourselves without the need for additional software licenses or experts."

Johannes Rehrl, Manager Global Sales Tools at Palfinger

"6 Months in" Analytics: Figures for the PALFINGER XR app

Over 8,000 app downloads (iOS and Android)

Over 20,000 views of the 3D visualizations (SmartVu®'S)

Over 130,000 page views

Read more at palfinger.com: https://www.palfinger.com/de/news/palfinger-xr-app-neue-3d-produkt-modelle-in-live-size-echtgrosse-und-erweiterten-features_n_183086

PALFINGER AG has created and launched a brand new “Palfinger XR” app with Vuframe® that will bring products and manuals closer to thousands of customers in the future.

The customer: PALFINGER AG

Founded in 1932, the company is known worldwide for the most innovative, reliable and economical lifting solutions used on commercial vehicles, ships and stationary equipment. Innovation and further internationalization of products, processes and services are the three pillars of the company's strategy, along with flexibility.

Solutions, which are used on commercial vehicles, ships and stationary equipment. Innovation and further internationalization of products, processes and services form the three pillars of the corporate strategy, alongside flexibilization. In order to focus on the challenges and opportunities of the digital transformation, a fourth pillar has been added to the tried-and-tested strategy: PALFINGER 21st stands for new core competencies, new approaches, new products, services and business models in the digital age.

PALFINGER in figures at a glance

1,534 millioneuros in revenue in 2020

10,824 employees worldwide

34 production and assembly sites

5,000 manufacturing and assembly sites

Demo video of the PALFINGER XR app

The challenge: Own administration and compact, secure data

From the agency to the SaaS platform

Originally, an XR app was developed with an agency. However, it soon became clear that PALFINGER was constantly developing its products and in order to reflect these changes in the app, the company always had to turn to the agency - with the associated costs, of course.

In addition, two important requirements could not yet be met:

Complex, animated 3D models of the lifting machines could not yet be compressed as small as desired without causing a loss of visual quality.

The question of data security for the 3D models played out, which were created from design data, could also not yet be adequately answered.

PALFINGER therefore turned to Vuframe because the platform allows users to manage the app themselves and is unique on the market in terms of data compression and data security thanks to its proprietary Aura 3D technology.

The solution: The PALFINGER XR app from Vuframe®

Use in various areas

The XR app solution kills two birds with one stone and serves two use cases at once - it is a sales solution and digital customer service at the same time:

In the app, the product portfolio can be presented by sales staff in 3D and augmented reality. The digital twins easily solve logistical challenges, especially for large crane constructions.

The app's AR marker recognizes videos stored in operating instructions that serve to illustrate PALFINGER machines and visually explain processes, for example. A classic, physical manual is therefore digitally supported for the customer. Palfinger then manages the content of the AR marker and the app structure itself in Vuframe Studio.

How the AR marker of the PALFINGER XR app works

Special feature: the AR marker

Seamlessly combining reality and digital

By selecting the AR marker in the PALFINGER XR app, customers can read additional digital information from the operating instructions using their smartphone or tablet camera. In most cases, these are stored videos that visually explain a specific procedure for operating or maintaining the crane in question.

The advantage: the videos are already stored in the right place in the operating instructions and there is no need to search by model and application, for example on the PALFINGER website, to find out specific handling or procedures. All that is needed is a mobile device so that customers can get the information they need even when they are standing directly in front of the machine in question.

“We have converted the existing PALFINGER XR app to the Vuframe platform. Now we can maintain & update the app ourselves without the need for additional software licenses or experts."

Johannes Rehrl, Manager Global Sales Tools at Palfinger

"6 Months in" Analytics: Figures for the PALFINGER XR app

Over 8,000 app downloads (iOS and Android)

Over 20,000 views of the 3D visualizations (SmartVu®'S)

Over 130,000 page views

Read more at palfinger.com: https://www.palfinger.com/de/news/palfinger-xr-app-neue-3d-produkt-modelle-in-live-size-echtgrosse-und-erweiterten-features_n_183086

PALFINGER AG has created and launched a brand new “Palfinger XR” app with Vuframe® that will bring products and manuals closer to thousands of customers in the future.

The customer: PALFINGER AG

Founded in 1932, the company is known worldwide for the most innovative, reliable and economical lifting solutions used on commercial vehicles, ships and stationary equipment. Innovation and further internationalization of products, processes and services are the three pillars of the company's strategy, along with flexibility.

Solutions, which are used on commercial vehicles, ships and stationary equipment. Innovation and further internationalization of products, processes and services form the three pillars of the corporate strategy, alongside flexibilization. In order to focus on the challenges and opportunities of the digital transformation, a fourth pillar has been added to the tried-and-tested strategy: PALFINGER 21st stands for new core competencies, new approaches, new products, services and business models in the digital age.

PALFINGER in figures at a glance

1,534 millioneuros in revenue in 2020

10,824 employees worldwide

34 production and assembly sites

5,000 manufacturing and assembly sites

Demo video of the PALFINGER XR app

The challenge: Own administration and compact, secure data

From the agency to the SaaS platform

Originally, an XR app was developed with an agency. However, it soon became clear that PALFINGER was constantly developing its products and in order to reflect these changes in the app, the company always had to turn to the agency - with the associated costs, of course.

In addition, two important requirements could not yet be met:

Complex, animated 3D models of the lifting machines could not yet be compressed as small as desired without causing a loss of visual quality.

The question of data security for the 3D models played out, which were created from design data, could also not yet be adequately answered.

PALFINGER therefore turned to Vuframe because the platform allows users to manage the app themselves and is unique on the market in terms of data compression and data security thanks to its proprietary Aura 3D technology.

The solution: The PALFINGER XR app from Vuframe®

Use in various areas

The XR app solution kills two birds with one stone and serves two use cases at once - it is a sales solution and digital customer service at the same time:

In the app, the product portfolio can be presented by sales staff in 3D and augmented reality. The digital twins easily solve logistical challenges, especially for large crane constructions.

The app's AR marker recognizes videos stored in operating instructions that serve to illustrate PALFINGER machines and visually explain processes, for example. A classic, physical manual is therefore digitally supported for the customer. Palfinger then manages the content of the AR marker and the app structure itself in Vuframe Studio.

How the AR marker of the PALFINGER XR app works

Special feature: the AR marker

Seamlessly combining reality and digital

By selecting the AR marker in the PALFINGER XR app, customers can read additional digital information from the operating instructions using their smartphone or tablet camera. In most cases, these are stored videos that visually explain a specific procedure for operating or maintaining the crane in question.

The advantage: the videos are already stored in the right place in the operating instructions and there is no need to search by model and application, for example on the PALFINGER website, to find out specific handling or procedures. All that is needed is a mobile device so that customers can get the information they need even when they are standing directly in front of the machine in question.

“We have converted the existing PALFINGER XR app to the Vuframe platform. Now we can maintain & update the app ourselves without the need for additional software licenses or experts."

Johannes Rehrl, Manager Global Sales Tools at Palfinger

"6 Months in" Analytics: Figures for the PALFINGER XR app

Over 8,000 app downloads (iOS and Android)

Over 20,000 views of the 3D visualizations (SmartVu®'S)

Over 130,000 page views

Read more at palfinger.com: https://www.palfinger.com/de/news/palfinger-xr-app-neue-3d-produkt-modelle-in-live-size-echtgrosse-und-erweiterten-features_n_183086

Contact us

Let's find out together how 3D visualizations can improve your business.

Jelena Rudan

Your contact at Vuframe for 3D in Mechanical Engineering and Digital Twins in 3D & AR.

Phone

+49 (0) 151 64 54 90 69

Contact us

Let's find out together how 3D visualizations can improve your business.

Jelena Rudan

Your contact at Vuframe for 3D in Mechanical Engineering and Digital Twins in 3D & AR.

Phone

+49 (0) 151 64 54 90 69

Contact us

Let's find out together how 3D visualizations can improve your business.

Jelena Rudan

Your contact at Vuframe for 3D in Mechanical Engineering and Digital Twins in 3D & AR.

Phone

+49 (0) 151 64 54 90 69

Contact us

Let's find out together how 3D visualizations can improve your business.

Jelena Rudan

Your contact at Vuframe for 3D in Mechanical Engineering and Digital Twins in 3D & AR.

Phone

+49 (0) 151 64 54 90 69

Read more success stories from companies

Read more success stories from companies

Read more success stories from companies

Read more success stories from companies

How a Virtual Steak is revolutionizing Weber-Stephen’s Product Presentation

Nina Ebbing

Training Manager

How a Virtual Steak is revolutionizing Weber-Stephen’s Product Presentation

Nina Ebbing

Training Manager

How a Virtual Steak is revolutionizing Weber-Stephen’s Product Presentation

Nina Ebbing

Training Manager

How a Virtual Steak is revolutionizing Weber-Stephen’s Product Presentation

Nina Ebbing

Training Manager

Efaflex: The Digital Gateway for Sales and Marketing

Christian Jacob

Head of Marketing

Efaflex: The Digital Gateway for Sales and Marketing

Christian Jacob

Head of Marketing

Efaflex: The Digital Gateway for Sales and Marketing

Christian Jacob

Head of Marketing

Efaflex: The Digital Gateway for Sales and Marketing

Christian Jacob

Head of Marketing

“The machine is right in front of me!” - Fette Compacting with XR at the Interpack

Volker Reinsch

Director Corporate Marketing & Communication

“The machine is right in front of me!” - Fette Compacting with XR at the Interpack

Volker Reinsch

Director Corporate Marketing & Communication

“The machine is right in front of me!” - Fette Compacting with XR at the Interpack

Volker Reinsch

Director Corporate Marketing & Communication

“The machine is right in front of me!” - Fette Compacting with XR at the Interpack

Volker Reinsch

Director Corporate Marketing & Communication

Vuframe provides the services and tools you need to bring your Machinery and Engineering products to life in 3D.

Built with ❤️ in Regensburg · © Copyright 2024 · Vu3D Software GmbH

Vuframe provides the services and tools you need to bring your Machinery and Engineering products to life in 3D.

Built with ❤️ in Regensburg · © Copyright 2024 · Vu3D Software GmbH

Vuframe provides the services and tools you need to bring your Machinery and Engineering products to life in 3D.

Built with ❤️ in Regensburg · © Copyright 2024 · Vu3D Software GmbH

Vuframe provides the services and tools you need to bring your Machinery and Engineering products to life in 3D.

Built with ❤️ in Regensburg · © Copyright 2024 · Vu3D Software GmbH